What should I pay attention to when using different types of bitumen melting equipment?

According to the configuration, layout and controllability of bitumen melting equipment, bitumen melting plant can be divided into three types: mobile, transportable and portable. What should be paid attention to in the production of bitumen melter equipment of different sizes? Let’s learn about it below!

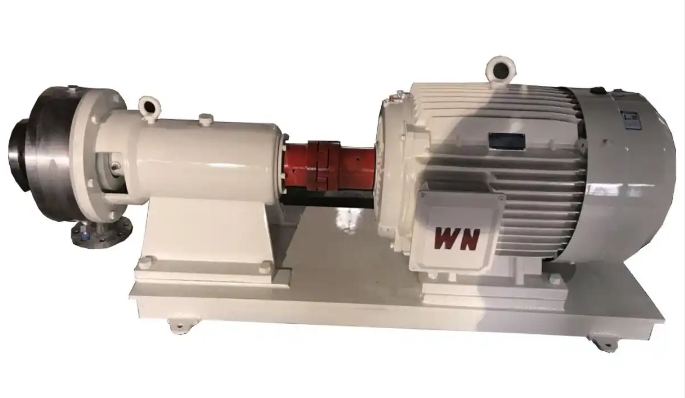

Bitumen melting plant is to fix the demulsifier mixing equipment, black anti-static tweezers, asphalt pump, automatic control system, etc. on a special support chassis. Because the bitumen melter equipment can directly change the production site, it is suitable for the production of emulsion bitumen in construction sites with decentralized projects, small usage and frequent movement.

The main components of the bitumen melting equipments are installed in one or two 60 standard containers. The bitumen melting plant is loaded and transported separately to complete the relocation of the construction site. With the help of asphalt melting equipments hoisting equipment, it is quickly installed and put into operation. Such bitumen melter plant has large, medium and small different configurations, which can meet different project requirements.

According to the configuration, layout and controllability of bitumen melting equipment, bitumen melting plant can be divided into three types: mobile, transportable and portable. What should be paid attention to in the production of bitumen melter equipment of different sizes? Let’s learn about it below!

Bitumen melting plant is to fix the demulsifier mixing equipment, black anti-static tweezers, asphalt pump, automatic control system, etc. on a special support chassis. Because the bitumen melter equipment can directly change the production site, it is suitable for the production of emulsion bitumen in construction sites with decentralized projects, small usage and frequent movement.

The main components of the bitumen melting equipments are installed in one or two 60 standard containers. The bitumen melting plant is loaded and transported separately to complete the relocation of the construction site. With the help of asphalt melting equipments hoisting equipment, it is quickly installed and put into operation. Such bitumen melter plant has large, medium and small different configurations, which can meet different project requirements.

During the production, the viscosity of the bitumen melting equipment decreases with the increase of temperature. For every increase of 12℃, its dynamic viscosity decreases by about one time. When manufacturing bitumen melting equipment, the cultivated matrix bitumen must be heated to liquid before emulsion can be carried out. In addition, in order to integrate the dissolution capacity of the colloid mill into the bitumen melting plants, the bitumen melting equipment generally controls the dynamic viscosity of the cultivated matrix bitumen to be about 200cst. The lower the temperature, the higher the viscosity of the asphalt melting plants. Increasing the pressure of the asphalt pump and the colloid mill will make the bitumen melting equipment unable to emulsify.

In order to prevent the water content in the finished product from being vaporized and multi-effect evaporated during the production of the bitumen melting equipment, it is also difficult to heat the temperature of the cultivated matrix bitumen of the bitumen melting equipment too high. Generally, the temperature of the finished product at the inlet and outlet of the colloid mill should be controlled to be lower than 85℃. The temperature of the asphalt melting equipment during production and the key control method of the viscosity of the asphalt melting plant should be properly operated according to the instructions, so that its characteristics can be fully demonstrated. There are many different models and specifications of bitumen melting equipment.

Because general bitumen melter equipment also has different classifications, when manufacturing modified material bitumen melting equipment, it is necessary to pay attention to whether the commonly used raw materials are required for general asphalt melting plant and ensure quality and quantity. Asphalt melting equipment is a compound of high molecular weight nitrogen oxides, which is very sensitive to temperature. When the temperature is higher than 180°C, the bitumen in the bitumen melting plant dissolves into dispersed carbon, and the precipitation of cementite and bitumen melting equipment substances seriously affects the elongation and adhesion of bitumen, and affects the properties and performance of bitumen.

Temperature is an important factor affecting the properties and performance of bitumen melting plants, so the heating temperature and heating time must be strictly controlled. If the temperature of the bitumen melting plant is too high or the heating time is too long, the performance of the bitumen melting equipment will be affected to varying degrees, thereby affecting the quality of construction. The temperature of the vulcanized rubber asphalt melter equipment must be maintained during use.