Detailed explanation of the composition of emulsified asphalt equipment, there is always something you don’t know

Emulsified asphalt equipment is an indispensable equipment in road construction and one of the basic equipment for waterproof coatings. What are the components of emulsified asphalt equipment? Today, we will explain the various parts of emulsified asphalt equipment in detail.

Required parts

Asphalt pump: a device for supplying asphalt to the colloid mill.

Emulsion pump: a device for supplying emulsion to the colloid mill.

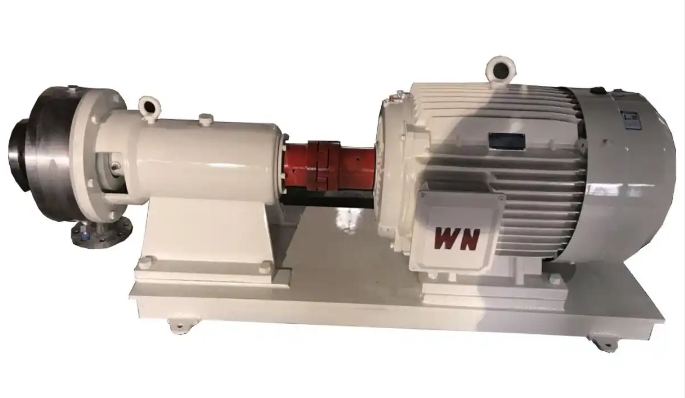

Colloid mill: a device for mixing, homogenizing and emulsifying asphalt and emulsion.

Control system: a device for controlling the flow of asphalt and emulsion, and the start and stop of various pumps.

Emulsion blending: a device for mixing water, emulsifiers and other additives.

Water heating part: a device for heating water.

Emulsified asphalt equipment is an indispensable equipment in road construction and one of the basic equipment for waterproof coatings. What are the components of emulsified asphalt equipment? Today, we will explain the various parts of emulsified asphalt equipment in detail.

Required parts

Asphalt pump: a device for supplying asphalt to the colloid mill.

Emulsion pump: a device for supplying emulsion to the colloid mill.

Colloid mill: a device for mixing, homogenizing and emulsifying asphalt and emulsion.

Control system: a device for controlling the flow of asphalt and emulsion, and the start and stop of various pumps.

Emulsion blending: a device for mixing water, emulsifiers and other additives.

Water heating part: a device for heating water.

Optional device

Metering device: a device for measuring the flow or quality of asphalt and emulsion. If the metering device is not selected, only low-grade emulsified asphalt can be produced.

Asphalt secondary heating device: secondary heating of low-temperature asphalt in the storage tank. If asphalt stirring is added, asphalt can be blended to produce special emulsified asphalt. If not selected, the production can only be carried out after the upper-level asphalt storage tank is heated to the process temperature. The applicability of the emulsified asphalt equipment is reduced.

Emulsifier adding device: add the emulsifier to the mixing tank after metering or diluting. If not selected, the emulsifier can be manually poured into the mixing tank.

Acid adding device: add the acid to the mixing tank after metering. If not selected, the acid can be manually poured into the mixing tank.

Cooling device: use water to cool the emulsified asphalt, which saves energy and increases the stability of the emulsified asphalt. If not selected, the emulsified asphalt cannot be cooled.

Supporting device

Asphalt storage tank: store base asphalt or modified asphalt.

Water tank: store water, which can be replaced by a well.

Boiler: steam boiler or thermal oil furnace, if the emulsified asphalt equipment adopts a burner type, this part can be omitted.

Emulsified asphalt storage tank: store emulsified asphalt. If the amount is small, only an asphalt spreader can be used.