How to add bitumen emulsifier

There are many types of bitumen emulsifiers, and there are many classification methods. For specific classifications, please refer to previous articles. The raw materials required for the production of emulsion bitumen are: bitumen, water and bitumen emulsifier. High-standard emulsion bitumen requires adding additives and adjusting acid. According to whether acid adjustment is needed in the emulsion bitumen production process, it can be divided into two categories: emulsion bitumen that requires acid adjustment and emulsion bitumen that does not require acid adjustment.

There are many types of bitumen emulsifiers, and there are many classification methods. For specific classifications, please refer to previous articles. The raw materials required for the production of emulsion bitumen are: bitumen, water and bitumen emulsifier. High-standard emulsion bitumen requires adding additives and adjusting acid. According to whether acid adjustment is needed in the emulsion bitumen production process, it can be divided into two categories: emulsion bitumen that requires acid adjustment and emulsion bitumen that does not require acid adjustment.

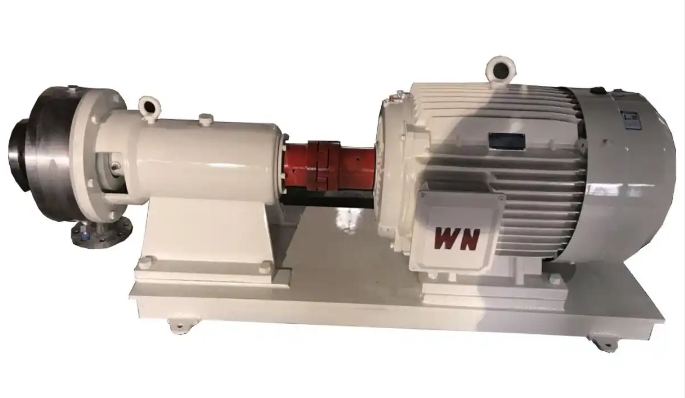

1. The production process for producing emulsion bitumen that does not require acid adjustment is to add bitumen and emulsifier aqueous solution through equipment to produce emulsion bitumen.

Refer to the recommended dosage on the packaging barrel to add emulsifier. For example: the addition amount of bitumen emulsifier is 0.6%-0.8%, that is, 6-8 kg of bitumen emulsifier is needed to produce one ton of emulsion bitumen. The recommended amount of emulsifier addition in initial production is 8 kg. (Later, it can be based on the finished product. The stability can be adjusted by itself.) To produce emulsion bitumen with a solid content of 50, 16 kg of emulsifier is added to one ton of water at about 70°C. After the addition of the bitumen emulsifier is completed, turn on the soap tank stirring device, stir evenly, and turn on the soap pump to produce emulsion bitumen.

2. An additional step in the production process of producing emulsion bitumen for micro-surfacing construction that requires acid adjustment is to adjust the pH value in the emulsifier aqueous solution. At this time, the addition amount of bitumen emulsifier is 1.8%-2.5%. It is recommended to add 2.5% emulsifier for initial production. For emulsion bitumen with a solid content of 60, 1 ton of water can produce 2.5 tons of emulsion bitumen, that is, adding 2.5*25=62.5 kg of emulsifier to 1 ton of water. Then, adjust the acid as required to adjust the pH value to 2.0-2.5. You need to use pH test paper to adjust the acidity. After the emulsifier and hydrochloric acid are added, stir evenly to start producing emulsion bitumen.