What key points should be paid attention to when feeding emulsified asphalt equipment?

What key points should be paid attention to when feeding emulsified asphalt equipment? When it comes to emulsified asphalt equipment, I don’t know how much you know about it? What should you pay attention to when adding materials?

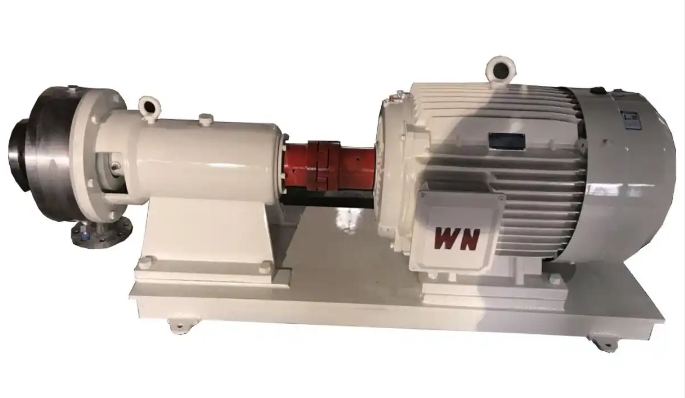

The black anti-static tweezers grinding wheel of the emulsified asphalt equipment does not have a heated collet. Before use, you must add the appropriate amount of diesel and let the black anti-static tweezers circulate for 3 to 5 minutes to generate heat (the temperature after operation is 80 ~100 degrees) open the stop valve on the oil delivery pipe to drain the diesel engine in the engine. The temperature of the black anti-static tweezers grinding wheel must be around 80 to 100 degrees before the material can be loaded and put into production. If there is a heated collet, the grinding wheel must be heated before starting, and then the material is loaded and put into production.

What key points should be paid attention to when feeding emulsified asphalt equipment? When it comes to emulsified asphalt equipment, I don’t know how much you know about it? What should you pay attention to when adding materials?

The black anti-static tweezers grinding wheel of the emulsified asphalt equipment does not have a heated collet. Before use, you must add the appropriate amount of diesel and let the black anti-static tweezers circulate for 3 to 5 minutes to generate heat (the temperature after operation is 80 ~100 degrees) open the stop valve on the oil delivery pipe to drain the diesel engine in the engine. The temperature of the black anti-static tweezers grinding wheel must be around 80 to 100 degrees before the material can be loaded and put into production. If there is a heated collet, the grinding wheel must be heated before starting, and then the material is loaded and put into production.

When adding materials, be sure to open the emulsified oil valve of the emulsified asphalt equipment first, and then open the asphalt valve to avoid problems with the motor stator. The inner diameter gauge of the emulsified asphalt equipment is generally adjusted to the 0 position at the original factory. Adjust the gap to the right. The change of one small grid on the inner diameter gauge is 0.01mm. It can be adjusted to the ideal gap anytime and anywhere as needed.